One of the hottest products on the cannabis market right now is Delta-8. Just about every CBD shop now sells Delta-8 products. So do do some medical cannabis pharmacies and dispensaries. The question is this: where is all the Delta-8 THC coming from? Cannabis plants do not produce enough of it to support the current industry.

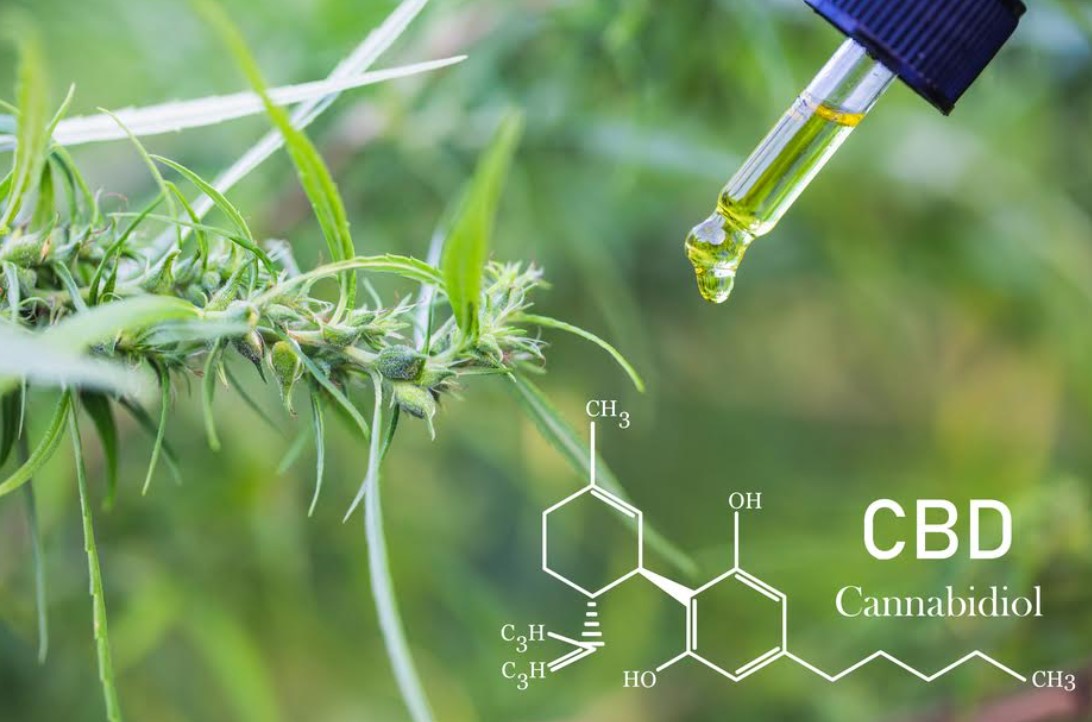

To understand where Delta-8 comes from, you have to know a little bit about cannabis plants and their cannabinoids and terpenes. The two most common cannabinoids are CBD and THC. But there are over a hundred cannabinoids in the many varieties of cannabis plants. As for terpenes, they are the compounds that give plants their unique odors.

Extracting Cannabinoids and Terpenes

Manufacturers interested in CBD and THC turn to companies like CedarStoneIndustry for state-of-the-art extraction and distillation equipment. CedarStoneIndustry and its competitors provide equipment to both hemp and marijuana processors looking to extract all sorts of cannabinoids and terpenes.

Extraction usually involves some sort of solvent, though there are other ways to get at cannabinoids and terpenes. Once extracted, a cannabinoid concentrate is distilled and then subjected to chromatography to further isolate the cannabinoids and terpenes manufacturers want. This brings us to the idea of getting your hands on Delta-8 THC.

A Naturally Occurring Cannabinoid

As previously stated, there are more than a hundred cannabinoids in hemp and marijuana plants. Delta-8 is just one of them. Unfortunately, it comprises less than 1% of all cannabinoid content in plant material, which is not enough. A typical cannabis plant doesn’t produce enough Delta-8 to make extracting and distilling it worthwhile. So where does all the Delta-8 THC come from? A lab.

Delta-8 THC is considered an isomer of its closest cousin, Delta-9. As an isomer, it has the same molecular makeup. What makes it different is its distinct arrangement of molecules. In a lab, Delta-9 can be processed to create Delta-8. You simply rearrange the molecules.

It turns out that Delta-8 can be manufactured from several different cannabinoids. It is easiest to convert CBD into Delta-8, which is why most Delta-8 products are sold as CBD products. Manufacturers can convert CBD to Delta-8 quickly and cheaply.

How Conversion Happens

Converting CBD into Delta-8 THC is pretty straightforward in principle. Though there is quite a bit of science behind it, manufacturers follow a basic four-step process:

1. Dissolve CBD Extract

The first step is to dissolve CBD. Obviously, the CBD is extracted from plant material first. After extraction and distillation, the CBD is combined with a non-polar organic solvent. Heptane is a pretty typical choice.

2. Introduce an Acid

Introducing an acid to the mix instigates the rearrangement of CBD’s molecules. Various acids produce different results, so processors choose their acids based on what they want the final product to be like. Even today, processors are experimenting with different acids to create customized Delta-8 products.

3. Heat and Stir

At the risk of making this sound like a recipe, the solvent/CBD/acid mixture must be heated and stirred. Because various solvents and acids react differently to one another, heating and agitation are necessary to create the desired molecular reorganization. Some mixtures can complete conversion to Delta-8 in as little as an hour. Other mixtures have to be heated and stirred for up to 18 hours.

4. Delta-8 Separation

The final step is known as ‘washing and drying. What is really happening is that the Delta 8 is being separated from the mixture. The separated material is then added to other cannabinoids and terpenes during the manufacturing of CBD products.

Now you know where all that Delta-8 is coming from.